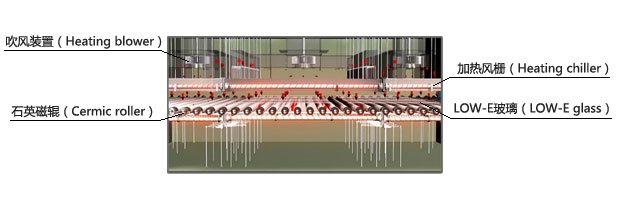

New forced convection type glass tempering furnace based on our ordinary type and passing type,re-designed, improved and replaced ‘old types in glass processing industry field.It marks senior glass,normal glass and low-e glass to achieve ideal standard in glass deep processing craft.

New forced convection type glass tempering furnace based on our ordinary type and passing type,re-designed, improved and replaced ‘old types in glass processing industry field.It marks senior glass,normal glass and low-e glass to achieve ideal standard in glass deep processing craft.

Characteristie

Matrix radiation and heating and grid-array forced convection heating is combined.

During glass run come and forth,grid-array forced quench blow evenly to ensure the even heati-ng coverage.

Heat resistant stainless steel material is adapted in heating chamber,ensure durable performance without distortion.

Hcating clcmonts arc mado of Ni-Cr clcctrothormal alloy,cnsuro hcating cvcnly,stcadiliy,flocty and long working life.

Thermal cycling quench blower is controled by inverter,eunsure air disributed on glass evenly.

Ceramic roller gear three-slot transmission ,interlocking,a fundamental solutiong to the channeling films,scratches caused by the transmission of sync.

Above six points adapt touch PC control.It up-graded to multi-point touch.“Hidden-trouble al-arm” and “Fault alarm” functions are added and imporves white mist,stress spots,scratches.

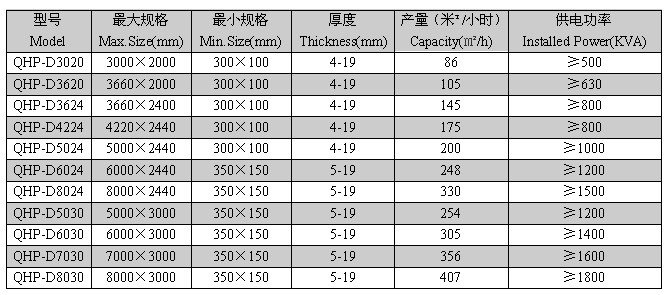

Parameters

Remarks:in the table the size take the millimeter as a unit.The output according to 5 millmeter glass 80% loading rate and 100% rate of finisshed products computation. Glass thickness scope fluc-tuation can cause capacity change.

E-mail:qhbljx@126.com

TLE:(+86)335-3321389